In an era where precision and efficiency are paramount, the demand for high-quality Mould Inserts has surged across various industries. As we look ahead to the technological trends shaping 2025, it becomes evident that the evolution of Mould Inserts is at the forefront of innovation, driven by advancements in materials, design, and manufacturing techniques. This blog aims to explore the critical strategies that premier Chinese manufacturers are employing to produce exceptional Mould Inserts that not only meet but exceed the expectations of modern production processes. By uncovering the best practices and cutting-edge technologies, we will guide you on how to leverage these insights to enhance your operations and unlock the potential of excellence in your projects.

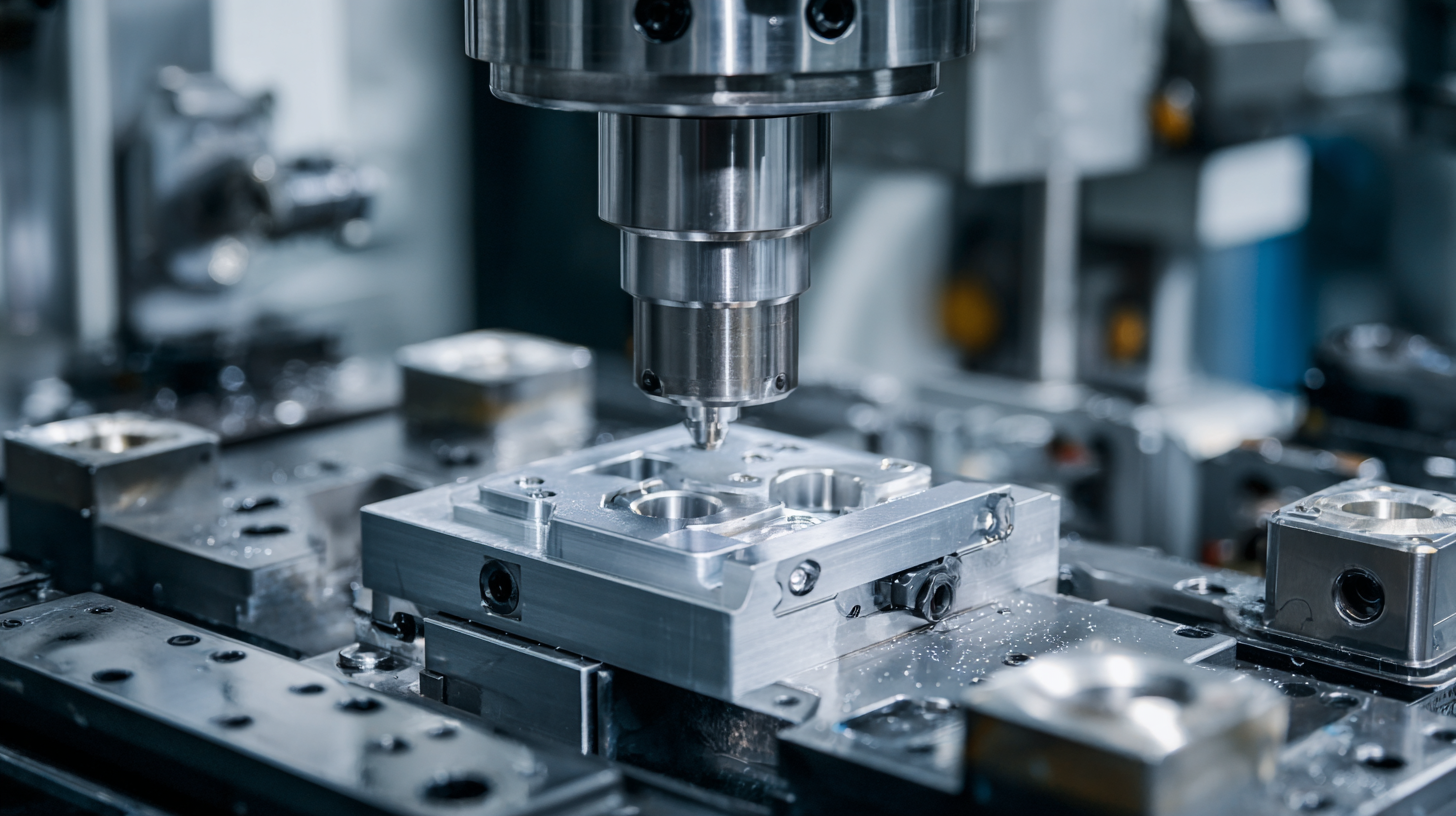

Mould inserts have become crucial components in modern manufacturing, serving as the backbone of many production processes across various industries. These precision-engineered tools enhance efficiency by facilitating the rapid production of high-quality parts. With the ability to create complex shapes and maintain tight tolerances, mould inserts play a significant role in reducing scrap and optimizing material usage. This efficiency not only accelerates the manufacturing cycle but also supports sustainable practices by minimizing waste.

As manufacturers strive to achieve excellence, partnering with a premier Chinese manufacturer for mould inserts can provide a competitive advantage. Chinese manufacturers have established a reputation for producing high-quality inserts that integrate advanced technology and innovative designs. Leveraging state-of-the-art materials and precision manufacturing techniques, they deliver products that enhance productivity and meet the stringent demands of industries such as automotive, aerospace, and consumer goods. By investing in superior mould inserts, companies can streamline operations, improve product quality, and ultimately boost their bottom line.

| Mould Insert Type | Material | Application Industry | Durability (Cycles) | Cost ($) |

|---|---|---|---|---|

| Standard Mould Insert | Steel | Automotive | 500,000 | 300 |

| Complex Design Insert | H13 Tool Steel | Electronics | 700,000 | 450 |

| High-Precision Insert | Aluminum Alloy | Medical | 300,000 | 600 |

| Heat-Resistant Insert | Titanium | Aerospace | 1,000,000 | 1200 |

| Multi-Cavity Insert | P20 Steel | Consumer Goods | 600,000 | 350 |

In the automotive sector, the use of mould inserts has revolutionized manufacturing processes, leading to enhanced precision and reduced production costs. According to a recent report by MarketsandMarkets, the global automotive moulding market is projected to reach $23.5 billion by 2025, driven by increasing demand for lightweight materials and efficient manufacturing. This growth underscores the critical role that innovative mould inserts play in producing high-quality components with intricate designs.

One outstanding case study highlights how a premier Chinese manufacturer implemented advanced mould insert technology to create lightweight vehicle parts. By utilizing high-performance materials and state-of-the-art manufacturing techniques, they achieved a 20% reduction in weight without compromising structural integrity. This innovation not only improved fuel efficiency but also met stringent environmental regulations, showcasing the dual benefits of adopting superior mould insert designs.

**Tips for Implementing Mould Inserts:** When considering mould inserts for automotive applications, prioritize material selection based on thermal and mechanical properties suited for the intended use. Collaborating with experienced manufacturers can ensure that you achieve optimal designs that enhance durability and performance. Additionally, investing in advanced simulation software can help visualize the effects of various mould designs, aiding in making informed decisions throughout the development process.

This chart illustrates the impact of mould inserts in various dimensions within the automotive sector, highlighting their significant contributions to fuel efficiency, weight reduction, durability, cost efficiency, and production speed.

When selecting the right mould insert, it is essential to consider several factors that directly impact production quality. Industry experts suggest that the precision of the mould insert affects the overall dimensional accuracy of the plastic components, with studies indicating that a mere 0.1 mm variance can lead to significant defects in large-scale production. This underscores the importance of meticulous selection processes when considering materials and design specifications.

Moreover, choosing a superior mould insert not only enhances the quality of the final product but also optimizes the manufacturing process. According to recent reports, using high-grade materials can increase the lifespan of mould inserts by up to 30%, reducing downtime for manufacturing lines and ensuring consistent production quality. Additionally, understanding the interaction between the plastic resin and the mould design can aid in minimizing defects caused by improper cooling or injection techniques, which are critical to maintaining efficiency in a competitive market. By focusing on these key aspects, manufacturers can unlock excellence in their production processes while maximizing output quality.

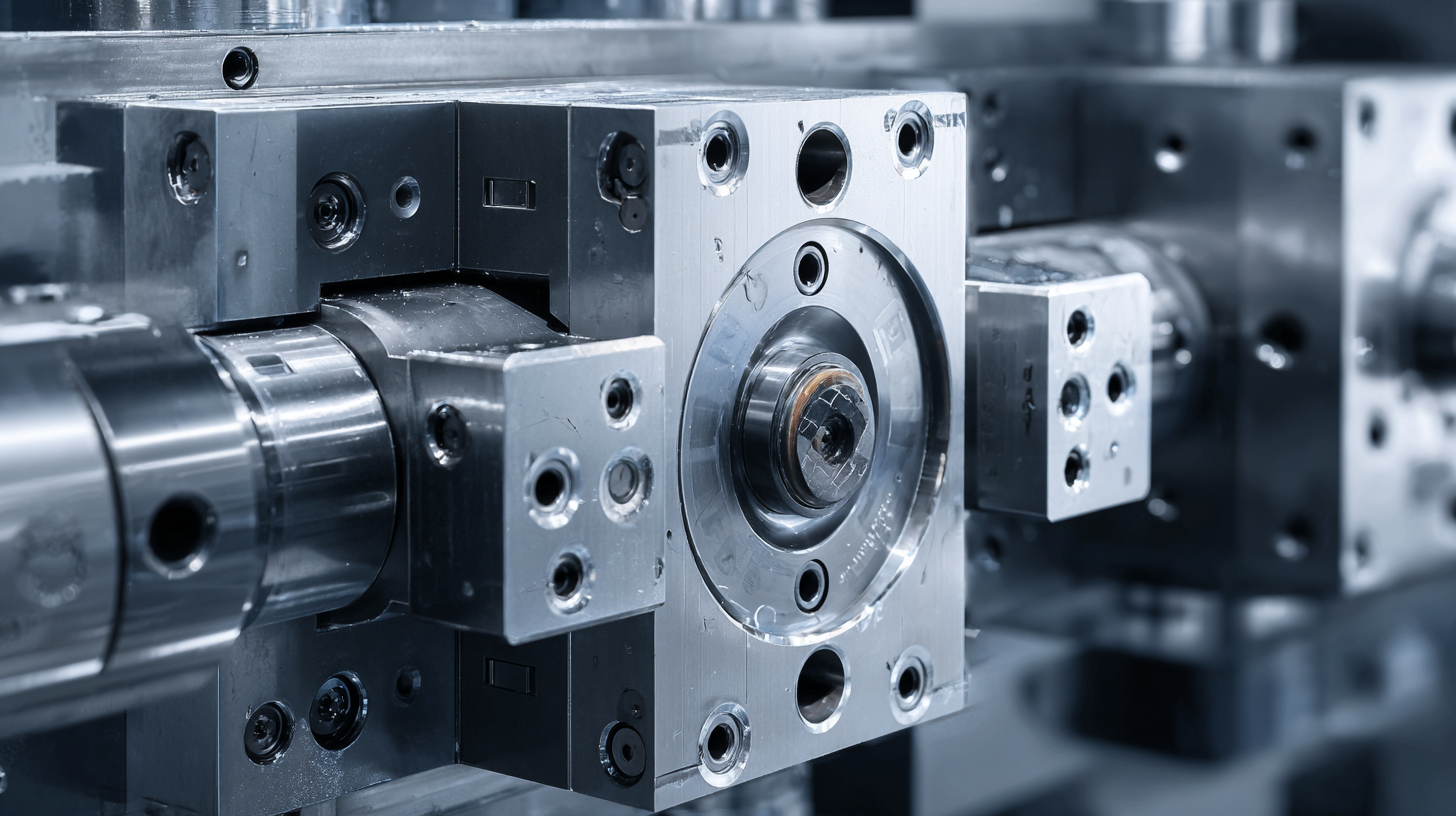

In large-scale production, cost-effectiveness is a crucial factor for manufacturers focusing on mould inserts. The integration of advanced technologies such as additive manufacturing and rapid tooling, especially in industries like pharmaceuticals and precision glass molding, has transformed traditional practices. The use of nano-graphitic carbon coatings on mould inserts has shown to enhance performance and longevity, ultimately reducing operational costs. Studies indicate that tooling can account for over 25% of the total cost in injection molding processes, highlighting the importance of optimizing material choices and manufacturing techniques.

Moreover, the design of hybrid deep learning models to evaluate costs in the plastic injection industry is gaining traction. By leveraging data from past production cycles and market trends, manufacturers can predict costs with greater accuracy, leading to informed decision-making. The exploration of different 3D printing technologies for the rapid production of mould inserts is also noteworthy; research suggests that these methods not only cut lead times but also improve the precision of the final products. Implementing such innovations positions manufacturers to remain competitive while maximizing cost efficiency in the ever-evolving landscape of large-scale production.

The mould insert industry has witnessed significant advancements driven by innovations and changing market demands. According to the latest market research report by Mordor Intelligence, the global moulding insert market is projected to grow at a CAGR of 5.3% from 2021 to 2026. This growth is propelled by the increasing need for high precision machining in various sectors such as automotive, consumer goods, and electronics. Manufacturers are increasingly adopting advanced materials and processes, enhancing the durability and performance of inserts, further escalating their market value.

Additionally, sustainability trends are shaping the mould insert technology landscape. A recent study by Technavio highlights that eco-friendly materials and recycling initiatives will not only reduce waste but also attract environmentally conscious consumers. The emphasis on automation and digital manufacturing techniques, such as additive manufacturing, is revolutionizing the production of mould inserts, allowing for quicker turnaround times and customized solutions. This technological shift not only improves efficiency but also fosters a competitive edge in an ever-evolving market.