Mold stamping is a critical process in the manufacturing sector, particularly in the production of precision components for various industries, including automotive, aerospace, and consumer electronics. According to a recent report by MarketsandMarkets, the global mold and die market is expected to reach USD 123 billion by 2025, growing at a CAGR of 6.1% from 2020 to 2025. This growth highlights the increasing reliance on efficient and effective mold stamping solutions to meet the rising demand for high-quality parts. As industries strive for productivity and innovation, sourcing the best mold stamping strategies becomes essential. In this blog, we will explore various examples and best practices that can streamline the mold stamping process, ensuring manufacturers remain competitive in an ever-evolving marketplace.

Identifying your business needs for mold stamping solutions is crucial for achieving optimal efficiency and product quality.

Begin by thoroughly assessing your project's specifications. Consider the materials you’ll work with, the volume of production, and the precision required. Understanding these factors will help you determine the type of mold stamping process that best suits your needs.

Identifying your business needs for mold stamping solutions is crucial for achieving optimal efficiency and product quality.

Begin by thoroughly assessing your project's specifications. Consider the materials you’ll work with, the volume of production, and the precision required. Understanding these factors will help you determine the type of mold stamping process that best suits your needs.

Tip 1: Conduct a needs analysis to pinpoint specific requirements, such as the complexity of design and tolerances. Collaborate with your engineering team to align the mold stamping capabilities with production goals. This proactive approach can prevent costly adjustments down the line.

Tip 2: Research potential suppliers and engage in discussions about their capabilities and limitations. Ask about their experience with similar projects and request samples of their work. This will provide insights into their quality standards and help you make informed decisions.

Additionally, consider the long-term implications of your choice. Factors such as maintenance costs, scalability, and material adaptability will also play a significant role in whether a mold stamping solution meets your ongoing business needs.

When evaluating potential suppliers for mold stamping solutions, it's crucial to consider key criteria that influence both performance and sustainability. Research indicates that supplier selection significantly impacts purchasing company performance, with a direct correlation between effective supplier evaluation and successful outcomes. Reports highlight a range of factors, including cost, quality, delivery time, and sustainability practices, which should be assessed holistically.

Sustainability has emerged as a pressing criterion in supplier evaluation frameworks. A comprehensive analysis presented in several studies outlines a hierarchical model for green supplier evaluation, incorporating six primary criteria and several sub-criteria grounded in the triple bottom line (TBL) principle—economic, environmental, and social. This approach allows organizations to navigate the complexities of selecting suppliers that not only meet their technical and economic needs but also align with sustainability goals. Moreover, the integration of analytical methods, such as the Analytical Hierarchy Process (AHP), is recommended to provide a structured evaluation process that emphasizes sustainable practices in supply chain management.

When it comes to sourcing the best mold stamping solutions, material selection plays a crucial role in achieving optimal performance. Different materials exhibit varying properties that can significantly impact the durability, weight, and cost of the final product. Among the most commonly used materials in mold stamping are aluminum, steel, titanium, and composites, each with its unique advantages and applications. For instance, aluminum is favored for its lightweight nature and resistance to corrosion, making it ideal for industries requiring high precision with less weight.

Recent studies have highlighted the importance of material choice in the context of performance characteristics. For example, a report indicated that titanium, while more expensive, offers superior strength-to-weight ratios suitable for high-performance applications. Meanwhile, traditional materials like steel continue to be prevalent due to their robustness and affordability. A fascinating development in the composites sector, particularly concerning carbon fiber, shows promising potential in reducing weight while maintaining an impressive stiffness, pushing the boundaries of the industry.

As industries evolve, the shift toward advanced materials like high-performance carbon fiber could redefine mold stamping processes. Notably, innovative research has emerged related to T800 carbon fiber, showcasing its application in various sectors, including cycling. This demonstrates a growing trend where manufacturers are increasingly looking for materials that not only fit their performance needs but also align with sustainability goals, driving further advancements in mold stamping technology.

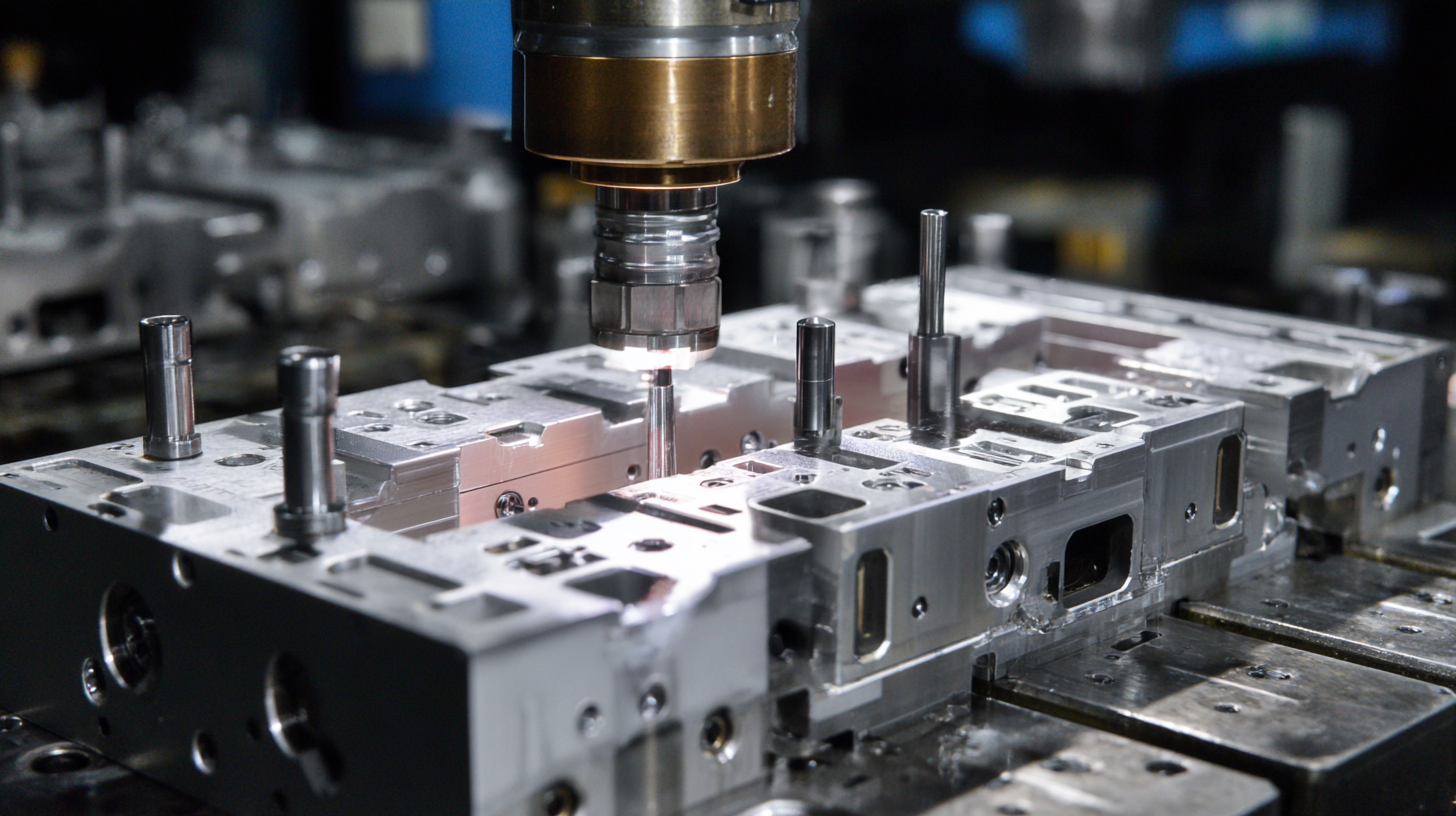

Mold stamping has evolved significantly over the years, integrating advanced technologies that enhance both efficiency and precision in manufacturing. One of the most impactful innovations is the introduction of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems. These technologies allow for meticulous design processes and streamline production workflows, resulting in decreased lead times and minimized errors. By utilizing CAD and CAM, manufacturers can precisely shape and mold materials to meet specific requirements, ensuring quality and consistency in the final product.

Another notable advancement in mold stamping is the rise of automated systems and robotics. Automation not only increases production speeds but also improves safety by reducing the need for manual handling of heavy materials. This shift toward automation allows companies to allocate human resources to more complex tasks that require critical thinking and creativity, ultimately enhancing overall productivity. Additionally, the integration of smart technology, such as IoT (Internet of Things) devices, enables real-time monitoring and adjustments during the stamping process, ensuring optimal performance and reducing waste. By embracing these latest technologies, organizations can source the best mold stamping solutions to stay competitive in a rapidly evolving market.

This chart illustrates the efficiency scores of various mold stamping technologies. The data reflects the performance of popular techniques such as 3D printing, laser cutting, CNC machining, die casting, and injection molding. Understanding these strategies can help in sourcing the best solutions for mold stamping needs.

When it comes to mold stamping solutions, building strong partnerships with your chosen provider is essential for achieving sustained success. According to a recent report by the International Association of Plastics (IAPD), over 70% of manufacturers credit their long-term operational efficiency to robust supplier relationships. These partnerships not only enhance collaboration but also facilitate innovation, enabling companies to stay competitive in a rapidly evolving market.

Effective communication and mutual understanding play pivotal roles in forging these partnerships. A study by the American Society for Quality (ASQ) found that organizations with high levels of supplier collaboration experience a 30% reduction in production costs and a 50% decrease in lead times. By engaging deeply with your mold stamping provider, you create an environment where both parties can share insights and optimize processes, leading to superior products and quicker turnaround times. Investing in a strong partnership is not just about outsourcing; it's about integrating expertise and fostering a cooperative mindset for mutual growth.