In today's rapidly evolving manufacturing landscape, maximizing your CNC experience has become crucial for achieving enhanced precision and efficiency. According to a recent report by the International Federation of Robotics, the global CNC machine market is projected to grow by 7.4% annually, highlighting the increasing reliance on these advanced technologies. Furthermore, a survey conducted by IndustryWeek found that 63% of manufacturers who invested in CNC optimization reported significant improvements in production accuracy and turnaround times.

To remain competitive, it is essential for manufacturers to not only invest in state-of-the-art CNC machinery but also to adopt best practices that optimize their CNC experience. By leveraging advanced programming techniques, regular maintenance, and skilled operator training, businesses can unlock the full potential of their CNC systems, leading to reduced waste, lower costs, and ultimately, a more agile manufacturing process.

CNC technology, or Computer Numerical Control, forms the backbone of modern precision manufacturing. It leverages computer programming to control machinery and tools, allowing for intricate designs and high accuracy in production. Understanding key concepts such as G-code, tool paths, and feed rates is crucial for operators looking to enhance their CNC experience. G-code is the language that instructs the machine on how to move, while tool paths refer to the trajectory followed by cutting tools during machining. By mastering these elements, manufacturers can optimize their operations for better precision.

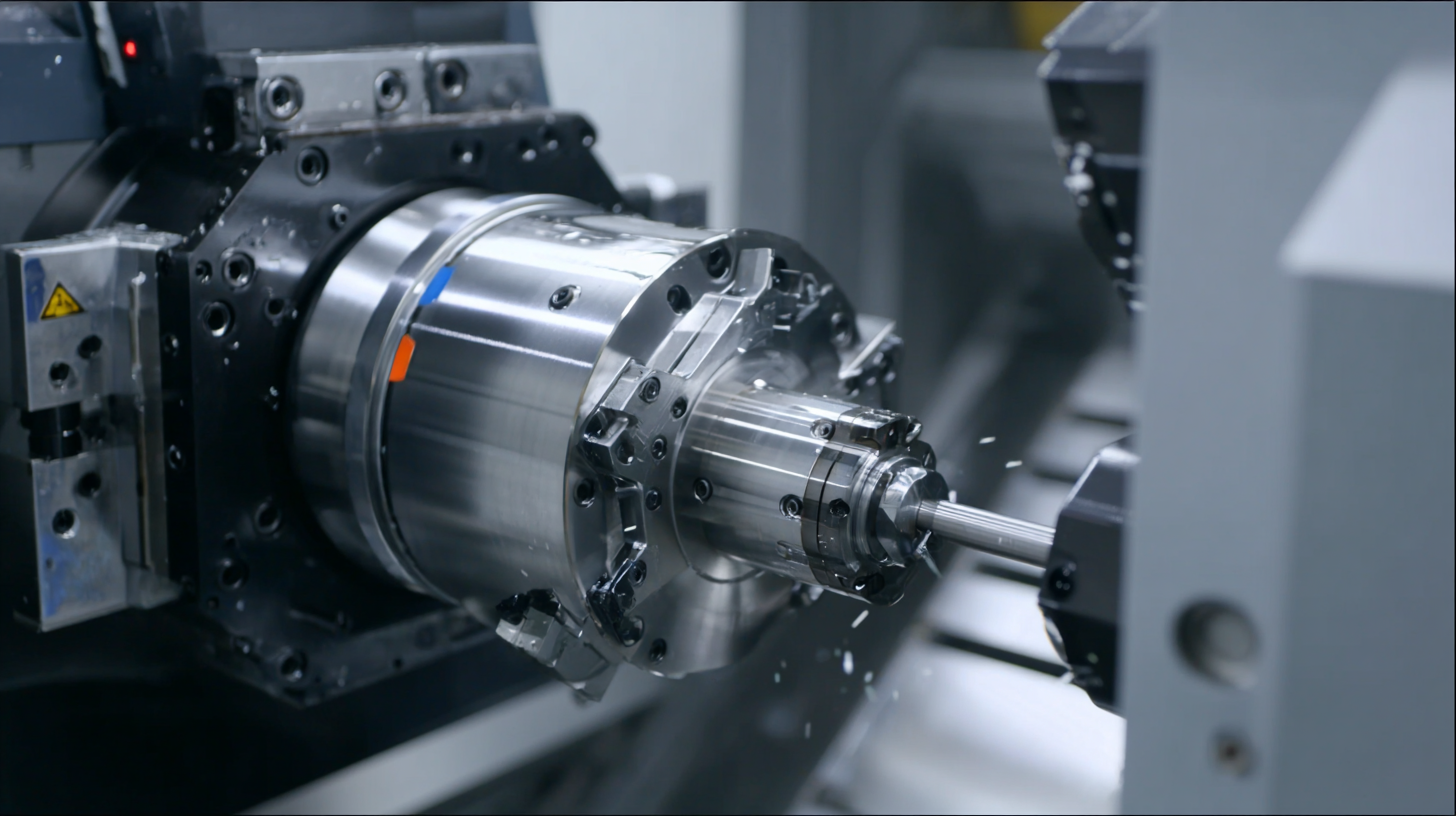

Choosing the right CNC machine is crucial for achieving precision and efficiency in manufacturing processes. In selecting a machine, consider the type of materials you will be working with, as different machines are optimized for various materials like wood, metal, or plastics. Additionally, evaluate the complexity of the parts you intend to produce. For instance, multi-axis machines are ideal for intricate designs, whereas simpler projects may only require a 3-axis CNC mill. Understanding your production needs will allow you to pick a machine that not only meets current requirements but can also adapt to future demands.

Another vital factor is the machine’s tooling and flexibility. CNC machines come with a variety of tooling options that can enhance precision and speed in production. Look for a machine that offers easy tool changes and a broad range of compatible tools, allowing for quick adjustments and versatility in production runs. Finally, consider the support and upgrades available from the manufacturer; a reliable service and a pathway for future enhancements can significantly impact your CNC experience and optimize productivity in the long run.

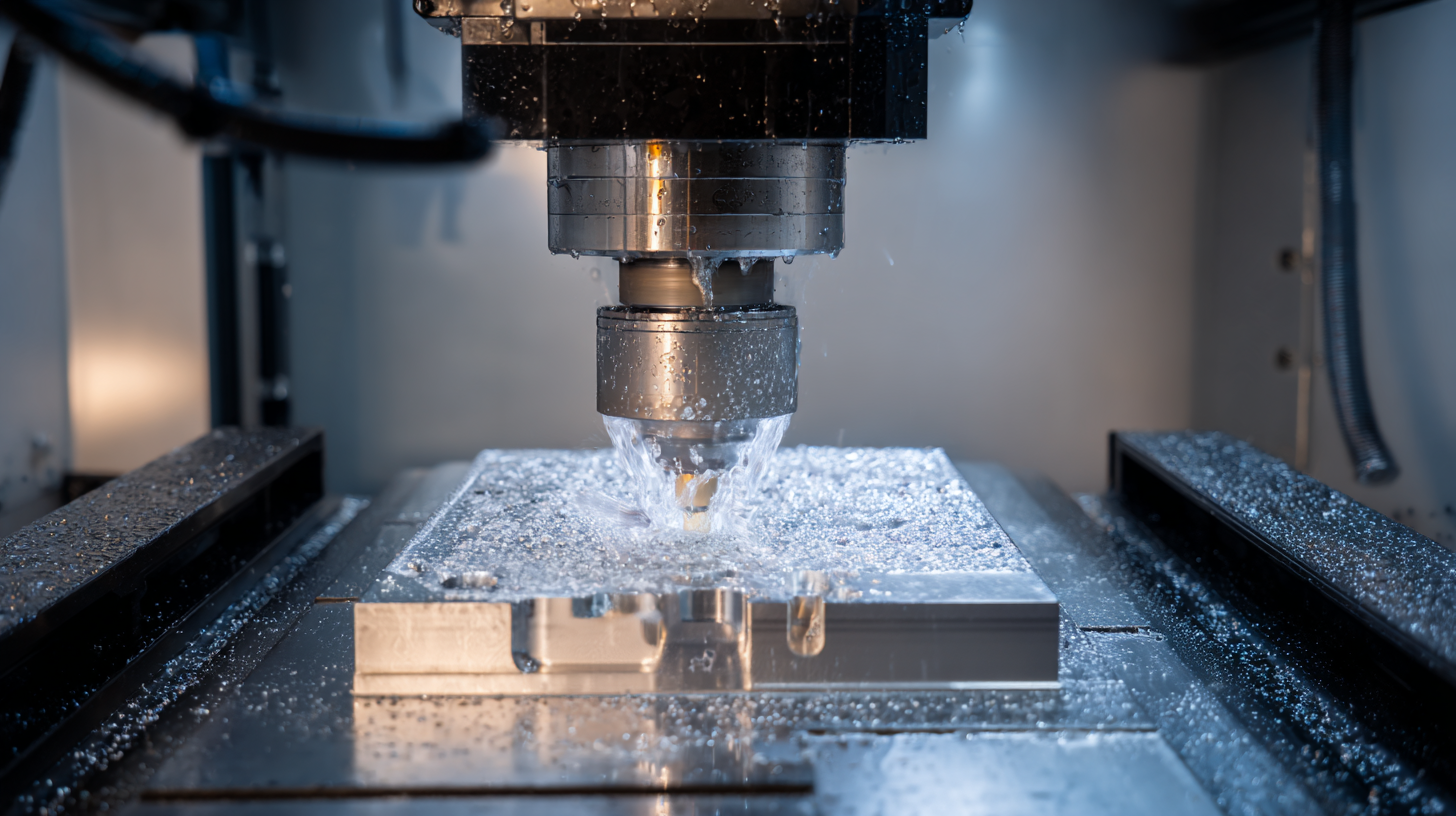

To maximize CNC efficiency and accuracy, optimizing the machine settings is crucial. Proper calibration of spindle speed, feed rate, and tool paths can dramatically affect the quality of the end product. Additionally, selecting the appropriate cutting tools and materials will enhance the overall machining process. Regularly updating these settings based on the specific requirements of each project ensures that the CNC machine operates at its best.

**Tips:** Always perform a test cut before moving on to full production. This allows you to assess the settings in practice and make necessary adjustments. Additionally, keep a close eye on tool wear; replacing worn tools promptly will maintain precision and prevent defects in your work.

Moreover, consider implementing advanced CNC software that allows for simulation and CAM capabilities. These tools can help visualize the machining process and identify potential issues before they arise in the actual operation. This proactive approach not only boosts efficiency but also minimizes waste and errors, leading to a smoother production workflow.

**Tips:** Take advantage of software features that allow you to program multiple tools and operations in one go. This reduces setup time and can lead to more complex designs being produced with ease.

Implementing software solutions is crucial for optimizing CNC operations, especially as the global CNC machine market is projected to grow significantly. Utilizing advanced CAD/CAM software allows manufacturers to streamline programming and simulation processes, thereby enhancing overall productivity. These integrated systems make it easier for businesses to manage complex CNC tasks, ensuring that precision and efficiency are maximized throughout the manufacturing cycle.

Furthermore, the integration of artificial intelligence into CNC machining is revolutionizing the way companies approach manufacturing. AI-driven solutions can analyze data in real-time, predict maintenance needs, and automate various machining processes. This not only minimizes downtime but also enhances precision, driving down costs and increasing output. As manufacturers look to adopt these next-generation technologies, embracing software advancements will be pivotal in transforming traditional CNC operations into more agile and efficient systems.

This chart illustrates the percentage of efficiency improvement achieved by various CNC software solutions. By implementing the right software, manufacturers can significantly enhance their CNC operations, leading to better precision and efficiency.

To enhance the skills of CNC operators, effective training techniques are crucial. One of the best practices is the implementation of hands-on training sessions that allow operators to interact with the machines directly. This experiential learning approach helps them understand the intricacies of CNC programming and setup, leading to improved precision in production. Additionally, simulation software can be utilized to replicate various machining scenarios, enabling operators to practice problem-solving and make adjustments in a controlled environment without the risks associated with real-time operations.

Another essential technique is fostering a culture of continuous learning. Encouraging operators to engage in regular workshops and seminars helps them stay updated on the latest CNC technologies and best practices in the industry. Peer-learning sessions are also beneficial, as they allow operators to share experiences and strategies to overcome common challenges. Incorporating feedback loops where operators can discuss their training experiences and suggest improvements can further optimize the training process, ultimately leading to enhanced efficiency and product quality in manufacturing operations.