The evolution of manufacturing techniques has ushered in a new era in Tool and Die Design, transforming traditional practices to meet the demands of modern production environments. As industries strive for increased efficiency and precision, it has become imperative to explore innovative methodologies that enhance the design and fabrication of tools and dies. This paper delves into the cutting-edge technologies and strategies that are redefining Tool and Die Design, from computer-aided design (CAD) systems to advanced machining technologies. The integration of automation and digital simulations not only streamlines the design process but also ensures higher quality and reduced lead times.

As we unlock the potential of these advancements, the future of Tool and Die Design promises greater adaptability and responsiveness to the ever-evolving landscape of manufacturing, paving the way for improved productivity and competitiveness in the global market.

The landscape of tool and die design is undergoing a transformative shift driven by emerging technologies, bringing unprecedented efficiency and precision to modern manufacturing. According to a report by McKinsey & Company, the adoption of advanced design technologies can enhance productivity in manufacturing by up to 20%. Key innovations such as computer-aided design (CAD), additive manufacturing, and simulation software are not just improving the design process but also enabling more complex geometries that were previously unachievable.

Moreover, the integration of artificial intelligence (AI) and machine learning is revolutionizing the decision-making process within tool and die design. A study by Deloitte predicts that AI-driven tools can reduce design time by as much as 30% while simultaneously improving the accuracy and quality of the designs. This shift allows engineers to focus on creative problem-solving rather than labor-intensive tasks, leading to a more agile and responsive manufacturing environment. As these technologies continue to evolve, organizations that embrace them will find themselves at a competitive advantage in the fast-paced manufacturing sector.

The integration of CAD/CAM software in tool and die design represents a pivotal shift towards enhanced design precision in modern manufacturing. According to a report by MarketsandMarkets, the global CAD market is expected to grow from $9.84 billion in 2020 to $15.83 billion by 2025, at a CAGR of 10.2%. This surge is largely attributed to the increasing demand for streamlined design processes and reduced time-to-market for new products. By utilizing sophisticated CAD tools, engineers can create highly detailed models that facilitate a more accurate representation of the final product, minimizing errors during the manufacturing phase.

Furthermore, the synergy between CAD and CAM technologies has proven to be indispensable in the optimization of production efficiency. A study by TechClarity indicates that companies integrating these technologies report up to a 50% reduction in design lead times and a 30% decrease in manufacturing costs. This close-knit collaboration enables real-time adjustments to designs based on machine capabilities, ultimately leading to better resource management and enhanced production workflows. As manufacturers continue to embrace these innovations, the landscape of tool and die design is set to evolve dramatically, meeting the ever-growing demands of precision and efficiency in a competitive market.

Additive manufacturing, also known as 3D printing, is revolutionizing the traditional landscape of tool and die design in modern manufacturing. A recent study by the Wohlers Report 2022 indicates that the global additive manufacturing market is projected to reach $41 billion by 2026, highlighting its increasing significance. By integrating additive techniques in tool production, manufacturers can create complex geometries with reduced lead times and costs. This shift not only enhances design flexibility but also allows for significant weight reductions, leading to improved efficiency in production processes.

Tips for implementing additive manufacturing in tool production include investing in the right technology and materials. It is essential to conduct thorough research to understand the best 3D printing technologies, such as selective laser sintering (SLS) or fused deposition modeling (FDM), that suit your specific needs. Additionally, collaborating with suppliers who specialize in additive manufacturing can provide valuable insights and access to advanced materials that bolster performance.

When transitioning to additive manufacturing, consider starting with small-scale projects to minimize risk while maximizing knowledge. Experimenting with prototypes can offer practical experience and refine processes before full-scale implementation. This trial-and-error approach can help companies anticipate challenges and adapt quickly, ultimately leading to a more successful integration of modern manufacturing techniques in tool and die design.

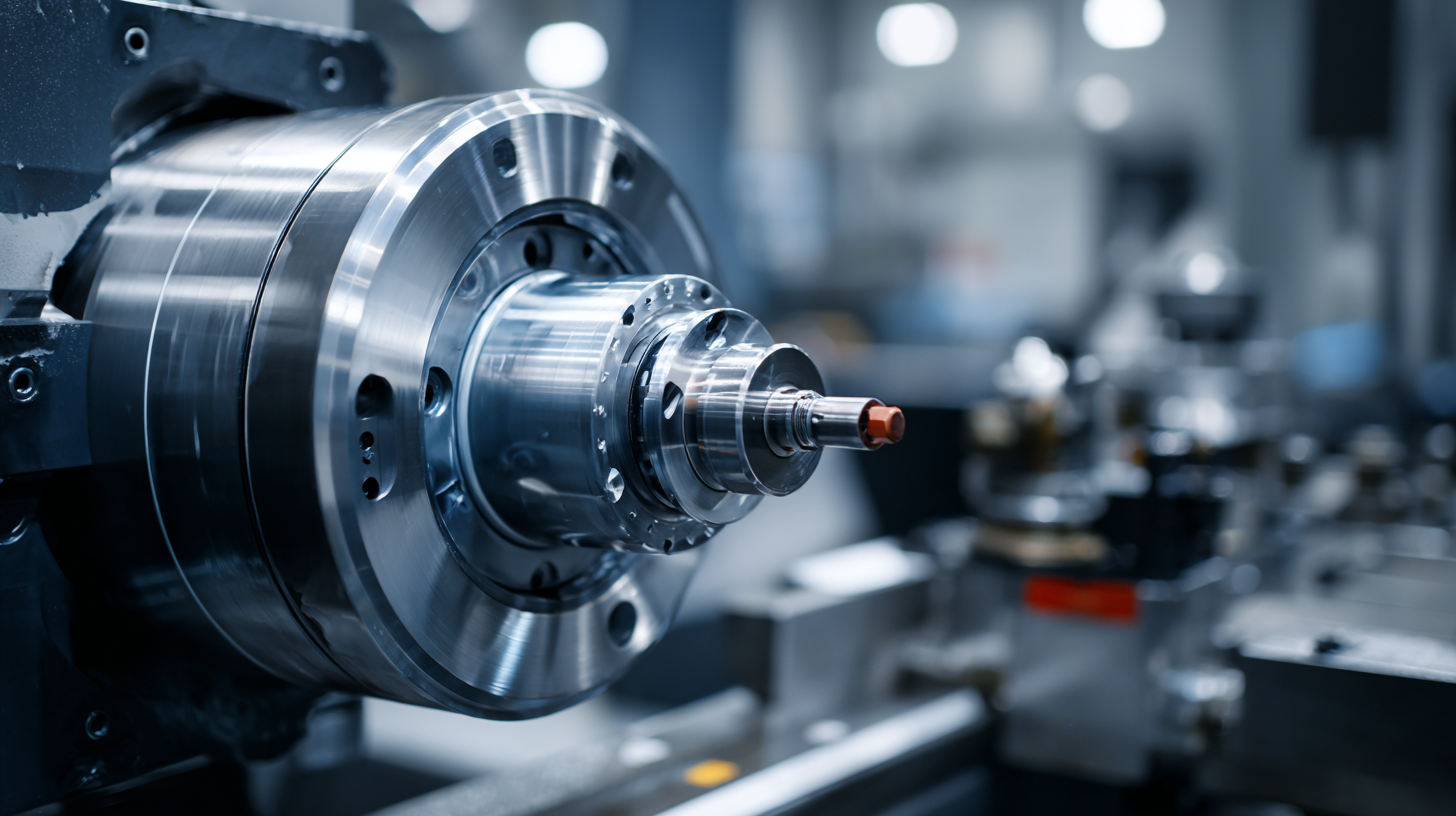

The integration of automation and robotics is poised to revolutionize die manufacturing, particularly for small-to-mid-sized manufacturers (SMMs) facing budget constraints and workforce challenges. By embracing collaborative robots and autonomous mobile robots (AMRs), these manufacturers can enhance productivity without the need for extensive capital investment. Robotics-as-a-Service (RaaS) models further enable SMMs to adopt cutting-edge automation technologies on a scalable basis, allowing them to maintain competitiveness in a rapidly evolving market.

Recent advancements highlight the effectiveness of robotics in streamlining complex manufacturing processes. Companies are increasingly leveraging AI and robotics to optimize production workflows, as seen in sectors ranging from automotive to pharmaceuticals. For instance, the use of digital tools and innovative motor technologies enables manufacturers to increase efficiency and accuracy in production. Furthermore, developments such as digital twin technology are paving the way for real-time communication between machines, thereby enhancing overall operational efficiency. As automation solutions continue to evolve, the future of tool and die design will undoubtedly benefit from these enhancements, leading to improved manufacturing outcomes.

In the realm of modern manufacturing, the Agile methodology is revolutionizing the approach to tool and die design. By prioritizing "just in time" production, teams can enhance their responsiveness to changing demands, leading to more streamlined workflows and improved product quality. This collaborative design approach fosters continuous feedback among stakeholders, enabling quicker iterations and innovations that meet market needs effectively.

As companies like Bel engage in digital transformation with strategic partners, they exemplify the shift towards a more integrated and sustainable model. Collaboration with experts not only accelerates the deployment of new technologies but also ensures that sustainability is woven into the fabric of product development. By applying best practices in collaborative design, organizations can maintain agility, adapt to consumer trends, and ultimately produce more efficient and responsible designs that resonate with modern values.