In the highly competitive manufacturing landscape, the significance of superior Mould Die Design cannot be overstated. According to a recent industry report by Markets and Markets, the global moulding market is projected to reach $369.2 billion by 2025, driven by increasing demand for precision components across various sectors. A well-executed mould die design not only enhances product quality but also reduces production costs and time. The design phase accounts for approximately 70% of the manufacturing costs; thus, investing in excellence at this stage is crucial for companies aiming to remain competitive.

This Ultimate Checklist for Achieving the Best Mould Die Design Excellence will delve into the essential elements and best practices that can lead to superior design outcomes, ensuring that manufacturers can maximize their efficiency and profitability while meeting the evolving demands of the market.

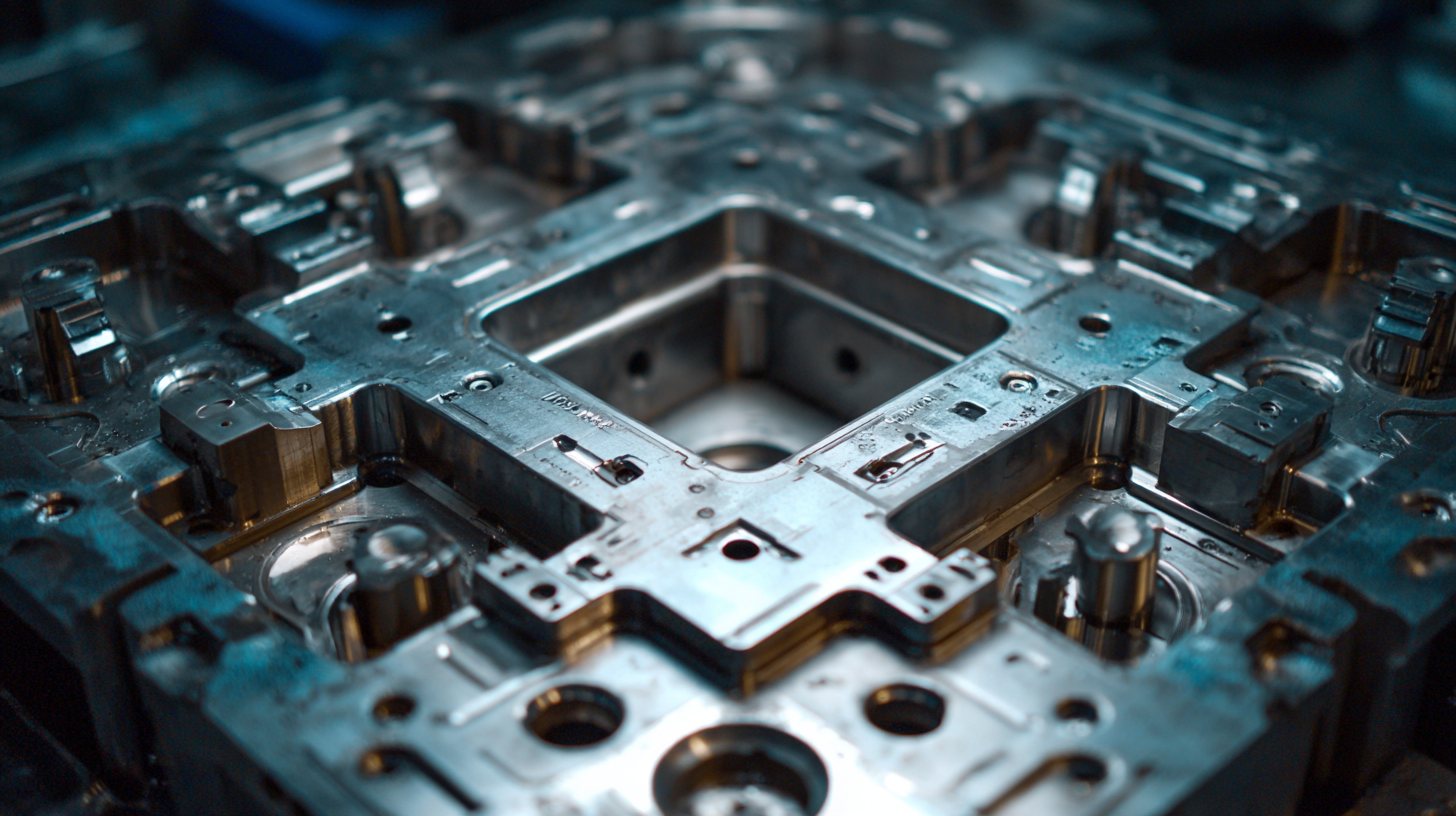

Effective mould die design is crucial for ensuring high-quality production and minimizing costs. One key principle is understanding material properties and their behavior during the moulding process. Selecting the right materials not only influences the durability and performance of the mould but also impacts the final product quality. Designers must consider thermal conductivity, shrinkage rates, and the compatibility of materials with the intended application to achieve optimal results.

Another essential aspect is incorporating proper cooling and heating systems within the mould. Efficient temperature management helps to reduce cycle times and improve the overall production rate. Designers should evaluate the placement of cooling channels to ensure uniform temperature distribution, which mitigates defects such as warping or inconsistency in dimensional tolerances. By applying these principles, mould die designers can create solutions that enhance productivity and meet the stringent demands of manufacturing environments.

When it comes to mould die design, avoiding common mistakes is crucial for optimal performance. A report by the Society of Plastics Engineers indicates that nearly 20% of production issues arise from design flaws. One prevalent mistake is underestimating the importance of draft angles. Insufficient draft can lead to difficulties in part ejection and increased wear on the mould, ultimately affecting product quality.

Tip: Always incorporate a minimum draft angle of 1° to 2° for easier part release and prolonged tool life.

Another common oversight is neglecting thermal management. According to a recent study by the American Society of Mechanical Engineers, temperature variations within mould dies can cause warping, leading to dimensional inaccuracies. Proper cooling channels should be designed to ensure uniform temperature distribution throughout the mould.

Tip: Use simulation software to analyze temperature flow and optimize cooling channel placement for enhanced efficiency. By addressing these design mistakes, manufacturers can enhance mould die performance and increase their overall production success.

When it comes to achieving excellence in mould die design, examining innovative examples across various industries provides invaluable insights. For instance, the automotive industry has continuously pushed the boundaries of mould die technology. According to a report by Deloitte, advancements in automotive manufacturing have led to a 15% reduction in part production time due to optimized mould designs, enhancing efficiency and lowering costs. This exemplifies how innovative die designs can transform production processes.

In the consumer goods sector, companies are increasingly adopting 3D printing techniques to create complex mould shapes that were previously impossible to achieve with traditional methods. A study by Wohlers Associates indicated that the global 3D printing market is projected to reach $35.6 billion by 2024, showcasing the growing importance of such technologies in mould design. This shift not only allows for intricate designs but also shortens the prototyping phase significantly, enabling faster market response.

**Tip:** When exploring mould die design improvements, consider integrating digital simulation tools that can predict performance and streamline the design process. Another tip is to stay updated with industry trends and technologies; attending relevant trade shows or webinars can offer fresh perspectives and innovative ideas for your designs.

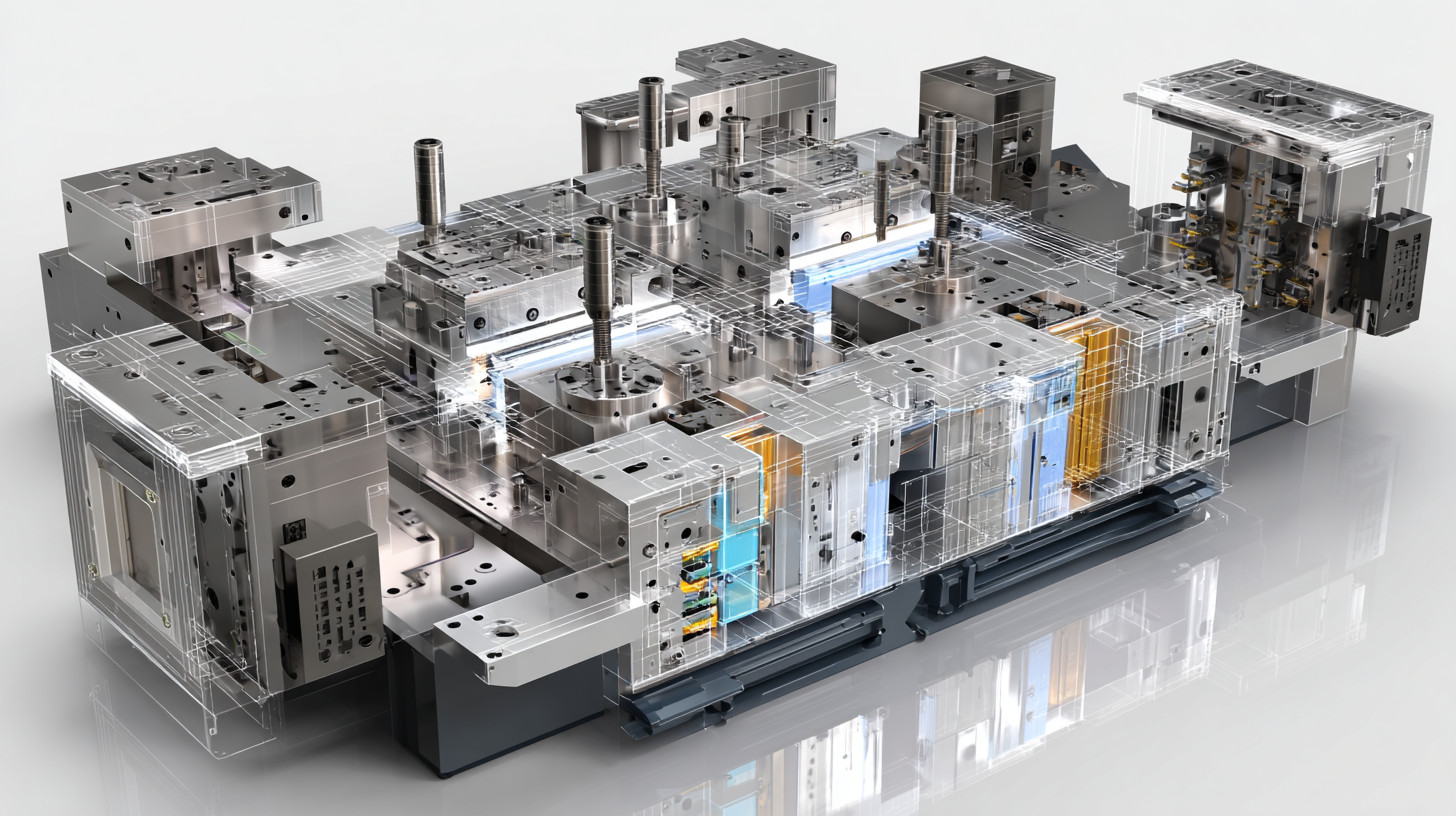

When it comes to mould die design, utilizing the right tools and technologies is crucial for achieving excellence. Essential software programs such as CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) systems are foundational in creating precise and efficient designs. These tools enable designers to visualize the die in 3D, optimize its functionality, and test various iterations before physical production. Additionally, advanced simulation software allows for the assessment of die performance under different conditions, thus minimizing the risk of costly errors during the manufacturing process.

Moreover, integrating technologies like additive manufacturing aids in prototyping mould dies more rapidly. This modern approach allows for the quick production of complex geometries that traditional methods might struggle to achieve. Furthermore, using data analytics can significantly enhance the design process by providing insights into manufacturing capabilities and limitations. By leveraging these essential tools and technologies, designers can ensure that their mould dies are not only high-quality but also tailored to meet specific production needs, paving the way for ongoing innovation in the industry.

Effective collaboration with mould die designers is crucial for achieving exceptional designs. Open communication is the foundation of a successful partnership. It’s essential to provide clear, detailed project requirements and expectations right from the outset. This helps designers understand your vision, timelines, and any specific constraints you may have. Regular meetings and updates enable both parties to address challenges swiftly, ensuring that the project stays on track.

In addition to communication, leveraging tools that facilitate collaboration can significantly enhance the design process. Utilizing shared digital platforms for design reviews allows for real-time feedback and adjustments, which can lead to more efficient decision-making. Offering constructive feedback is key; rather than focusing solely on what might be wrong, highlight what's working well alongside suggestions for improvements. By cultivating a team-oriented environment, you create an atmosphere where innovative ideas can flourish, ultimately leading to a mould die design that meets and exceeds expectations.

| Dimension | Description | Best Practices |

|---|---|---|

| Material Selection | Choosing the right materials for durability and performance. | Consult with material specialists to find the best match for the application. |

| Cooling System Design | Ensuring efficient cooling to minimize cycle time. | Use simulation tools to optimize the cooling layout. |

| Tolerance Specifications | Defining acceptable limits for mold dimensions and component fit. | Align tolerance levels with product final assembly requirements. |

| Design for Manufacturability | Creating designs that are easy to manufacture and assemble. | Involve production teams early in the design phase for feedback. |

| Prototyping Methods | Using prototypes to test design before full-scale production. | Leverage 3D printing technologies for rapid prototyping. |

| Communication Channels | Establishing clear communication among stakeholders. | Utilize project management tools for real-time collaboration. |