In the ever-evolving landscape of manufacturing, the precision of parts heavily relies on advanced Machining Cutting techniques. According to a recent report by the International Society for Precision Engineering, over 70% of manufacturers believe that mastering these techniques is essential for competitive advantage. The demand for precision continues to rise, pushing the boundaries of technology and innovation.

John Anderson, a renowned expert in Machining Cutting, states, “Precision is not just a goal; it’s the essence of quality in manufacturing.” His insight highlights the necessity of continuous improvement in methods. Current trends suggest a shift towards automation and intelligent systems to optimize cutting processes. Yet, many companies still grapple with conventional methods that hinder progress.

Despite the advancements, there is a concern regarding the industry’s reliance on outdated practices. A significant number of firms have yet to fully embrace digital tools. This hesitance can lead to inefficiencies, impacting overall productivity and quality. The challenge lies in integrating traditional techniques with modern innovations to achieve optimal results in precision machining.

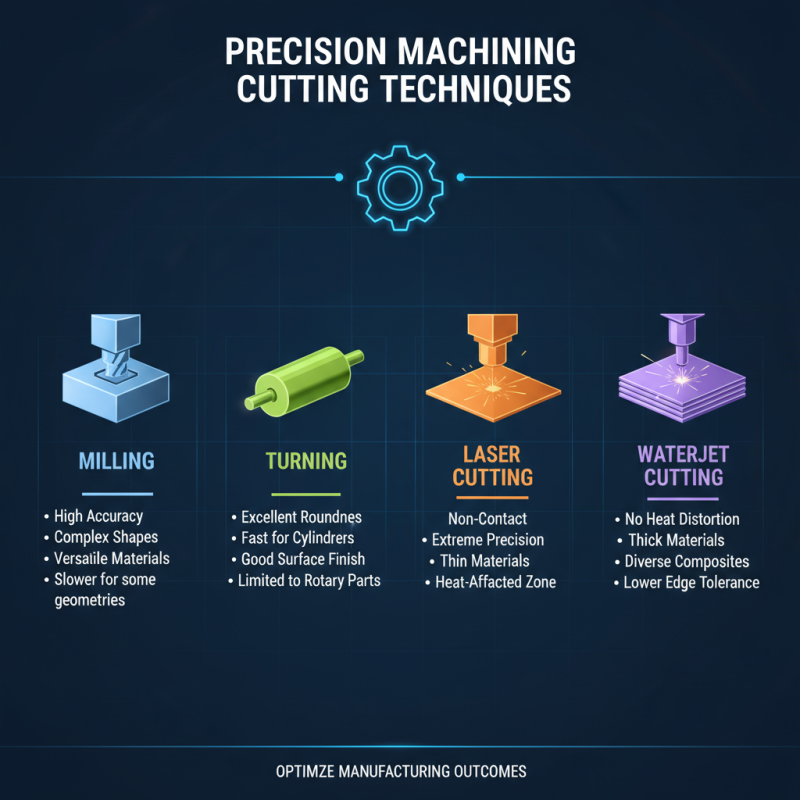

Machining cutting techniques are crucial for creating precision parts. Various methods exist, each with its pros and cons. Some techniques excel in accuracy, while others focus on speed or material versatility. Understanding each method's strengths can lead to better manufacturing outcomes.

CNC machining is a popular choice for precision parts. It uses computer-controlled tools to achieve tight tolerances. However, setting up CNC machines can be time-consuming and requires skilled operators. In contrast, laser cutting provides high precision with minimal material waste. Yet, it may not be suitable for thicker materials, limiting its applications.

Another technique is waterjet cutting, which utilizes high-pressure water to slice through materials. This method is versatile and can handle various materials but may lack the fine detail offered by lasers. Machinists often face challenges, such as tool wear and inconsistent finishes. Regular maintenance and tool calibration are necessary to ensure quality output. Staying informed on the latest advancements in machining techniques can also drive improvements in production efficiency and precision.

Machining precision is at the heart of manufacturing. Several key factors influence the accuracy of machined parts. Material properties, tool wear, and machine calibration are critical. According to industry reports, improper tool setup can lead to up to 30% of production errors. This statistic highlights the need for meticulous attention to detail.

Tips: Regularly inspect and calibrate tools. A small deviation can cause significant issues. In a recent survey, 45% of manufacturers reported that frequent maintenance improved their production quality.

Another essential factor is cutting speed. It directly affects the heat generated during machining. Excessive heat can alter material properties, leading to inaccuracies. Data reveals that a 20% increase in cutting speed may decrease tool life by up to 50%.

Tips: Adjust speeds based on the material being machined. Experiment with different settings to find the sweet spot. Sometimes, taking the time for adjustments pays off more than rushing through a job. Reflect on past experiences to improve future results.

| Technique | Description | Material Compatibility | Precision Level | Applications |

|---|---|---|---|---|

| Laser Cutting | Uses high-powered laser to cut materials with high precision. | Metals, Plastics, Wood | High | Aerospace, Automotive, Electronics |

| CNC Machining | Computer Numerical Control machining for intricate shapes. | Metals, Plastics, Composites | Very High | Medical Devices, Robotics, Prototyping |

| Water Jet Cutting | Uses high-pressure water jet to cut through various materials. | Metals, Stone, Glass | Moderate | Construction, Art, Signage |

| EDM (Electrical Discharge Machining) | Uses electrical discharges to create precision shapes in hard materials. | Tool Steel, Carbide | Ultra High | Tooling, Aerospace, Mold Making |

| Plasma Cutting | Utilizes plasma to cut through conductive materials. | Metals | High | Fabrication, Construction, Automotive |

In the realm of precision parts, various machining methods are utilized to achieve tight tolerances and high-quality finishes. CNC milling is a widely adopted technique. It removes material using rotating cutting tools. This method excels in producing complex shapes and features. However, controlling tool wear can be a challenge.

Another common method is turning. This process involves rotating the workpiece against a stationary cutting tool. It is ideal for creating cylindrical parts with smooth surfaces. Yet, maintaining accuracy during high-speed operations can often lead to discrepancies. The heat generated may cause dimensional shifts in the material.

EDM, or electrical discharge machining, is essential for intricate designs. It uses electrical discharges to erode material. This technique is particularly beneficial for hard materials. However, it can be time-consuming and costly. Selecting the right machining method depends on the specific requirements of the part. Identifying the optimal process ensures both cost-efficiency and precision.

Emerging technologies in machining are reshaping how we achieve cutting precision. Recent studies indicate that utilizing advanced tools and methods can lead to precision enhancements by up to 30%. For instance, the integration of artificial intelligence into machining processes enables better predictive maintenance and real-time adjustments. This leads to increased uptime and reduced error rates, optimizing overall efficiency in manufacturing.

3D printing and additive manufacturing are also becoming significant. They allow for complex geometries that traditional machining cannot achieve. Reports show that incorporating these techniques can cut machining time by nearly half while maintaining high accuracy. However, this technology still faces limitations in material options and scalability, which need to be addressed.

Moreover, the rise of automation in machining tools is noteworthy. Robotics streamline repetitive tasks but can introduce new challenges. These include workforce displacement and reliance on technology that may not adapt to every situation. As companies invest in these technologies, they must reflect on their implementation strategies to ensure a balanced approach between efficiency and human expertise.

Choosing the right cutting tools is crucial for precision machining. Not all techniques suit every material. It’s essential to analyze the material properties before making a decision. Hard metals require specific techniques compared to softer materials. Matching tool types to material hardness maximizes efficiency.

**Tip:** Evaluate your materials. Choose tools accordingly.

Consider the cutting speed and feed rate as well. These factors significantly impact the quality of the finished part. Slower speeds can lead to better surface finishes, while faster speeds enhance productivity. However, the right balance must be found. Too fast may wear tools prematurely, while too slow can be inefficient and costly.

**Tip:** Test various settings. Adjust speeds based on results.

Lastly, regularly review your cutting techniques. What works today may not be optimal tomorrow. Stay updated with industry changes. Continuous improvement leads to better outcomes and reduces waste. Reflecting on past projects can reveal areas for enhancement. Don't hesitate to experiment and learn.