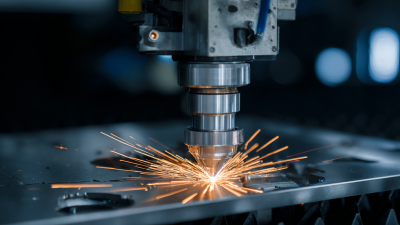

In the rapidly evolving landscape of manufacturing, the precision and efficiency of Electrical Discharge Machining (EDM) have become paramount for industry leaders aiming to maintain a competitive edge. According to a recent industry report by Machining Insights, the implementation of advanced EDM machine parts can boost operational efficiency by up to 30 percent. This statistic underscores the critical role that choosing the right EDM machine parts plays in enhancing production capabilities and minimizing resource wastage.

Dr. Alan Turner, a leading expert in machining technologies, emphasized the importance of innovation in EDM, stating, "The future of manufacturing lies in the precision of our tools; top-notch EDM machine parts are the backbone of this evolution." As manufacturers continue to seek ways to optimize their processes, understanding the key components that drive performance becomes essential. Our exploration of the top five EDM machine parts set to make a significant impact by 2025 will provide insights into the technologies that are reshaping the industry and allowing businesses to achieve unprecedented levels of precision.

In the rapidly evolving landscape of Electrical Discharge Machining (EDM), advancements in machine components are pivotal for enhancing precision and efficiency. The focus on innovation has led to the development of five critical EDM machine parts that can boost operational performance by an impressive 30 percent. Key innovations include upgrades in tool materials, improved electrode designs, and advanced control systems that ensure tighter tolerances and superior surface finishes. Such enhancements not only maximize productivity but also minimize waste, addressing the needs of the modern manufacturing environment.

Recent market analysis indicates that the EDM wire market is projected to grow significantly, with an estimated value of $136.27 million in 2025, escalating to approximately $314.03 million by 2033. This growth trajectory underscores the increasing demand for precision machining solutions in various sectors, including aerospace, automotive, and medical devices. As companies strive to remain competitive, investing in high-performance EDM components becomes essential in achieving greater accuracy and operational efficiency. Enhanced EDM technologies are thus not merely advantageous; they have become a necessity for businesses aiming to thrive in a market that values precision and rapid turnaround times.

The advancement of materials used in Electrical Discharge Machining (EDM) parts plays a pivotal role in enhancing precision and efficiency. Innovative materials, such as advanced alloys and composites, not only contribute to the longevity of EDM components but also significantly improve their performance during the machining process. These materials enable higher tolerances and better surface finishes, which directly influence the capabilities of EDM machines in producing complex geometries with minimal deviations.

In particular, the integration of digital twin technology alongside these advanced materials allows manufacturers to simulate and optimize the machining process before actual production. By creating a virtual replica of the EDM system, manufacturers can predict outcomes, identify potential issues, and fine-tune parameters to achieve desired results consistently.

This integration can lead to a 30 percent improvement in operational efficiency, confirming the importance of both material advancements and technological innovations in the EDM sector. Such developments not only enhance productivity but also broaden the application scope of EDM in industries requiring high precision, such as aerospace and medical device manufacturing.

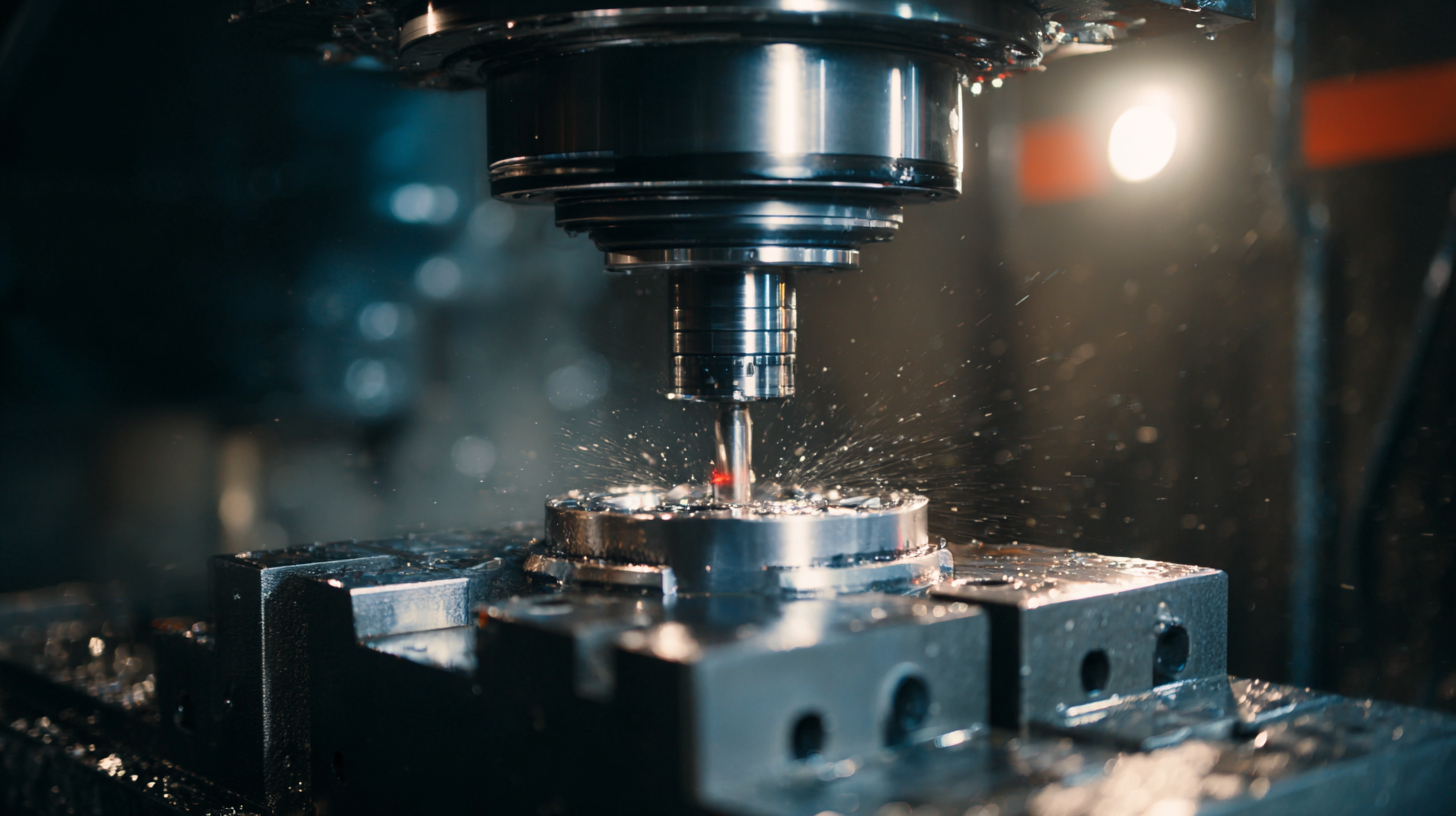

Optimizing the design of EDM (Electrical Discharge Machining) machines is essential for enhancing operational efficiency. By focusing on key components such as the power supply, servo mechanism, and cooling systems, manufacturers can significantly improve the performance and precision of machinery. The integration of advanced materials and technology in these essential parts can lead to improvements in thermal stability and reduced wear, ultimately contributing to a more reliable production process.

Incorporating features such as adaptive control systems and real-time monitoring significantly aids in fine-tuning machine operations. These innovations allow for immediate adjustments based on performance data, minimizing downtime and making processes more predictable. Moreover, efficient EDM machine design can lead to a decrease in energy consumption, thus providing not only economic benefits but also contributing to sustainable manufacturing practices by reducing waste and carbon footprint. Enhanced efficiency through optimized design supports manufacturers in meeting increasingly demanding production requirements while maintaining competitive quality standards.

The integration of advanced software in Electrical Discharge Machining (EDM) is revolutionizing precision and efficiency in manufacturing. By harnessing sophisticated algorithms and real-time data analytics, manufacturers can optimize every aspect of the EDM process. This includes precise control over cutting parameters, enhanced machine learning capabilities, and improved predictive maintenance. Such advancements can lead to a significant boost in performance, with estimates suggesting an increase in efficiency by up to 30 percent.

Recent innovations, particularly in purpose-built wire EDM machines, are exemplifying this trend. Designed to meet the stringent requirements of sectors such as aerospace and energy, these machines utilize integrated software to deliver unmatched precision. Enhanced features allow for real-time monitoring and adjustments, which minimizes downtime and maximizes output. As software continues to evolve, its impact on EDM capabilities is becoming increasingly pronounced, allowing manufacturers to achieve higher quality outputs and streamline operations effectively.

As we approach 2025, the EDM (Electrical Discharge Machining) technology landscape is set for remarkable transformations. The predicted trends highlight a shift toward greater precision and efficiency, with advanced machine parts enabling improvements by up to 30 percent. The integration of AI into EDM processes stands out as a significant enhancement. AI can revolutionize how these machines operate by not merely assisting in operations but autonomously planning and executing tasks. This capability will lead to smarter manufacturing processes, allowing for better resource allocation and optimized production schedules.

Tips for enhancing EDM efficiency include regularly updating software to incorporate the latest AI advancements, which can manage data analytics effectively. Additionally, investing in sensor technology can provide real-time monitoring of machine performance, helping to preemptively address potential issues before they affect production. With the EDM wire-cutting market valued at over $136 million in 2025, organizations that embrace these tech trends will undoubtedly gain a competitive edge.

Fostering a culture of continuous improvement by training staff on the latest EDM technologies can significantly impact overall efficiency. Encouraging collaboration between human operators and AI systems will not only enhance productivity but also ensure better quality control in machining operations. As the EDM landscape evolves, staying informed on these advancements will be crucial for businesses aiming to lead in the precision engineering sector.